Finned Tubes

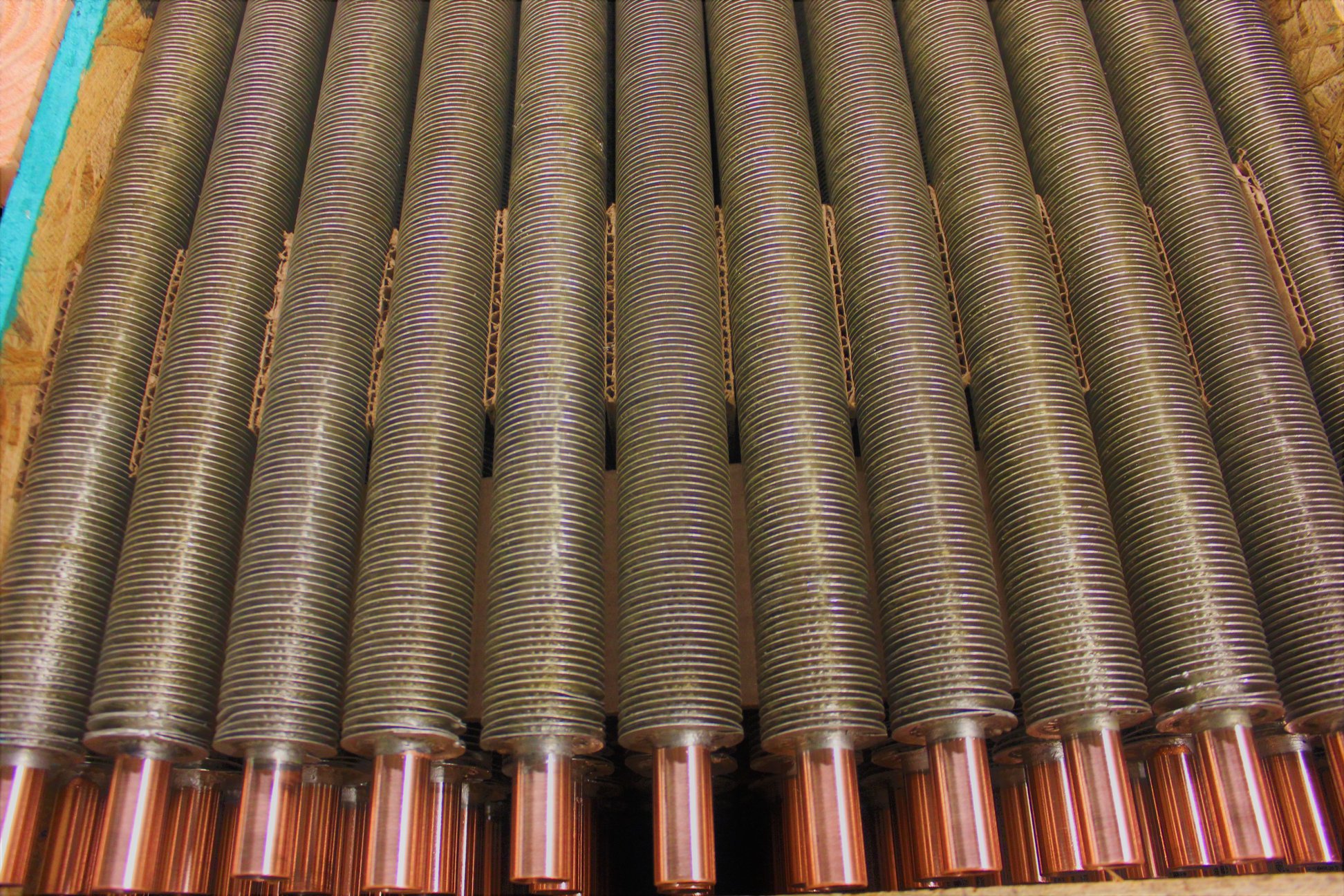

Helically Wound Finned Tubes, also known as extended surface tubing, are used in a variety of industries and heat transfer applications. We provide Finned Tubes for generator air coolers, bearing oil coolers, hydrogen & exciter air coolers in the power industry. Other Finned Tube and Finned Pipe applications include air compressors, counter top water distillers, egg hatcheries, lumber dry kilns, chillers, humidifiers, dehumidifiers, commercial & industrial boilers, heating and air conditioning units, radiators and air cooled heat ex-changers & condensers to name just a few. Unity Tube, Inc. offers several fin-to-tube attachment methods to satisfy your specific application.

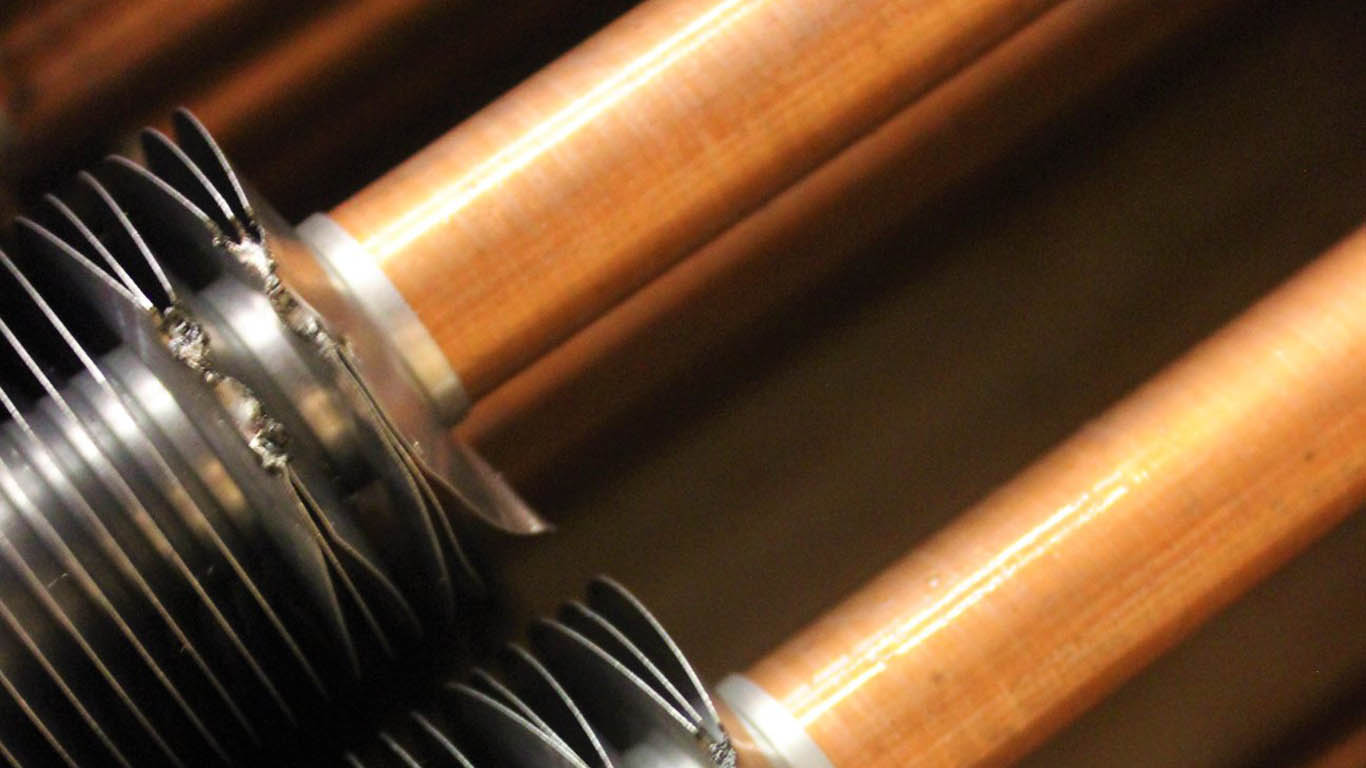

L-footed finned tubing offers maximum heat transfer at lower temperatures. The unique L-shaped design holds fins rigidly to withstand heat cycling and high velocity air vibration. L-foot tube attachment has always been considered highly efficient yet cost effective. Works best in temperatures below 450° F.

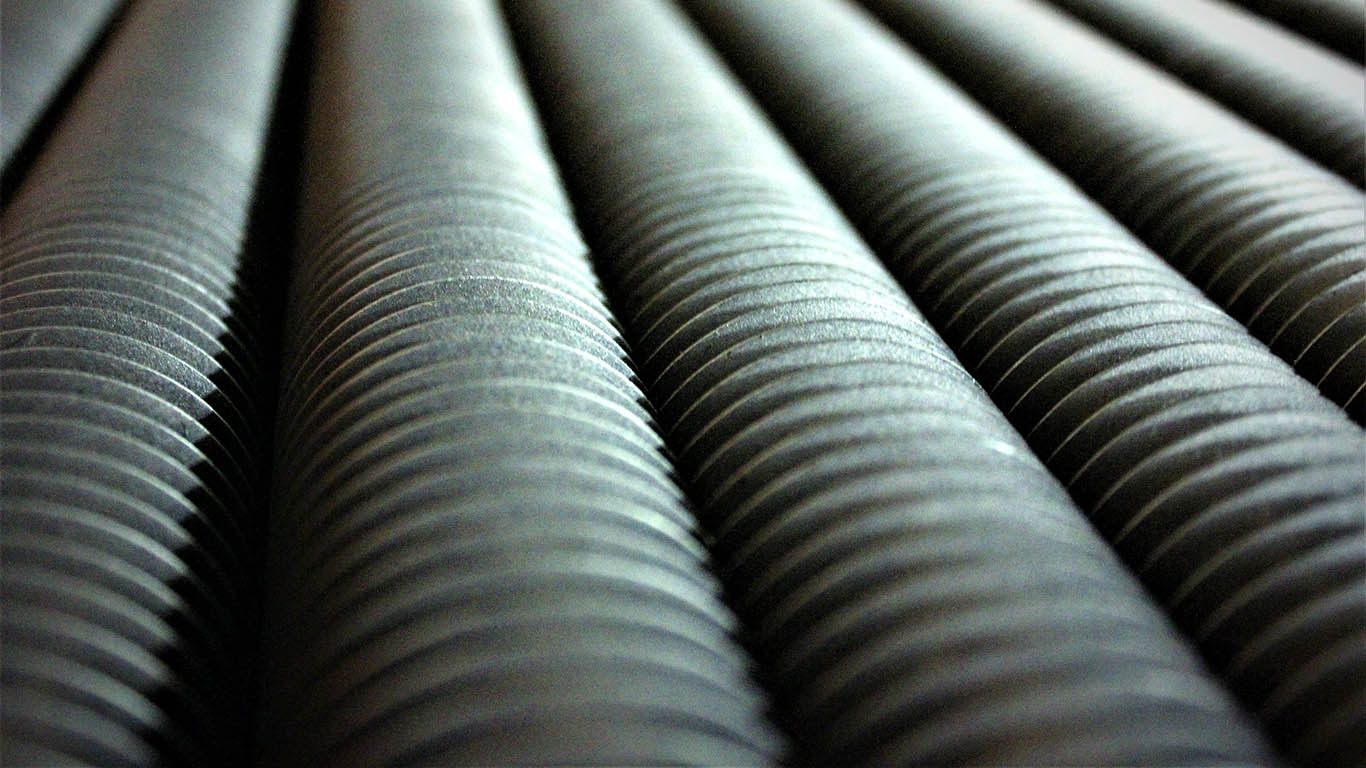

Unity Tube offers embedded finned tubing where exceptional thermal efficiency at higher temperature ranges with solid fin-to-tube contact is required. Fins are embedded or locked into the helical groove on the outside of the tube. Rollers press metal that has been removed from the groove against the base of the fin to form a lasting metal-to-metal bond. The type of fin to tube construction works best in temperatures below 750 degrees F.

Unity Tube offers our Edge Tension Finned Tubes, also known as Edge Wound Finned Tubes, in similar or dissimilar metals. Edge tension finned tubing is recommended for moderate duty in normal ambient air applications and on most low-temperature air cooled heat exchangers. During the actual finned tube process the fin material is tightly wound around the outside of the tube to secure good metals-to-metal contact of the base of the fin with the tube.

Unity Tube offers two distinct types of soldered finned tubing: The first is solder-coated finned tubing which covers the entire fin and tube surface with the alloy. Lead-free and tin-lead alloys are available for all soldered products. Soldered tubes are best used in applications where the temperature does not get above 425 degrees F. When required we can also provide a root soldering which involves a special technique that uses enough solder to create the bond between the tube and the base of the fin thus avoiding bridging between fins.

Brazed finned tubing from Unity Tube offers a seamless metallurgical bond between fin and tube. A seamless metallurgical bond results in this type of attachment being ideal for rigorous, high-temperature applications. When the temperature rises or falls the tube expands or shrinks due to temperature never relaxes its grip. Unity Tube offers brazed finned tubing in similar or dissimilar metals for increased heat transfer efficiency. The bond created between the tube and the fin ensures a stress-free, uniform, and non-porous contact. This bonding allows for thinner tube walls compared to a welded fin to tube joint.

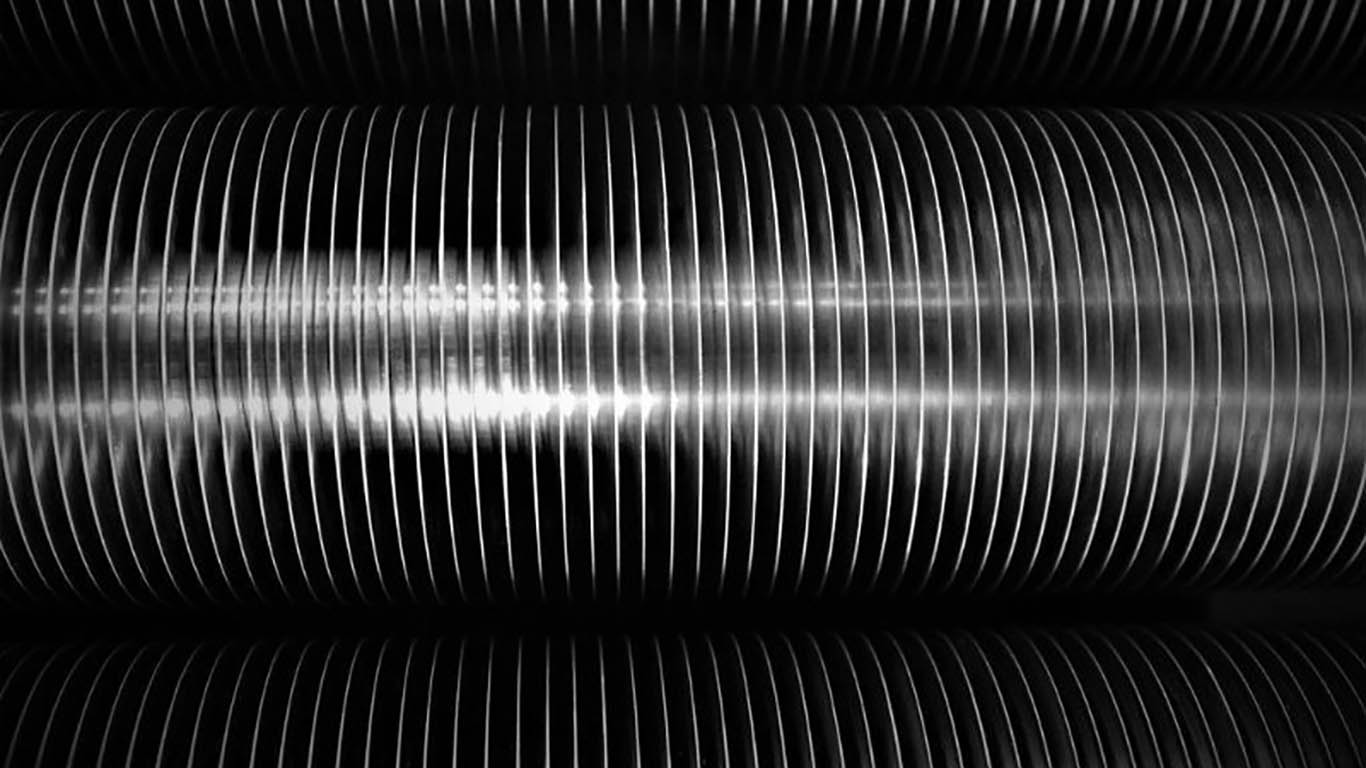

Integral Low Fin

Unity Tube offers Integral Low Fin Tubing in a wide variety of tube materials. Unlike our other types of fin attachments, Integral Low Fin Tubing does not use a separate fin strip material to apply the fins. Instead, the fins are raised from the surface of the tube itself. This type of surface enhancement does not remove metal from the tube but displaces it while keeping the starting outside diameter measurements intact. This type of finned tube is commonly used in Shell & Tube Heat Exchangers as an enhanced alternative to a Prime Surface Tube.